1. Name of the project

-

CASE_STUDY

-

Case_printingcompany is a printing offset printing company

-

Test_metalsheetcomany is a metal sheet processing company

-

Both companies are located in the Zürich area in Switzerland

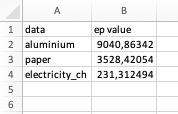

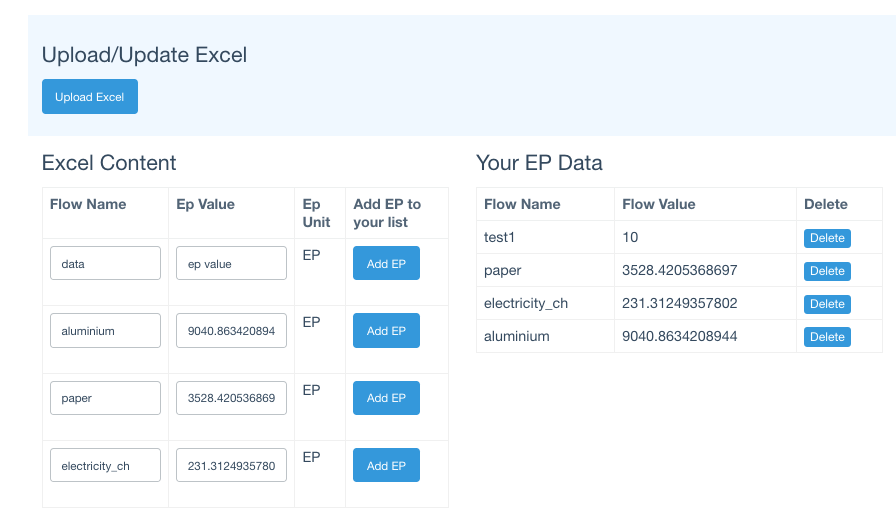

My EP Data

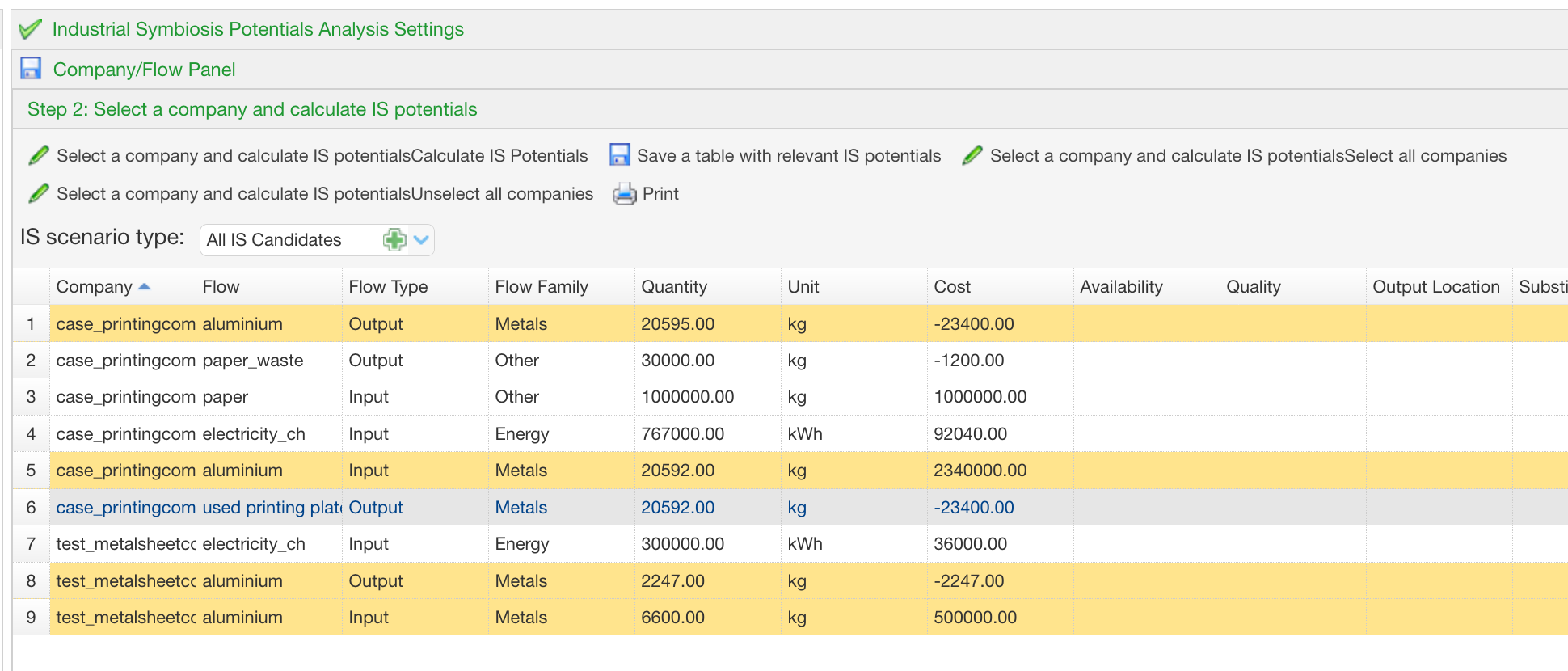

Case_printingcompany:

Flows

-

Input: Offset aluminum printing plates: 23'400 units, size per unit: 1030 x 790 x 0.4 mm, weight per unit 0.88 kg, material Al 99.9%, Costs: about 100 CHF/unit

-

Input: Electricity: 767'000 kWh, costs 0.12 CHF/kWh

-

Input: Graphic paper: 1’000 tons, costs 1’000’000 CHF

-

Output: Used offset aluminum printing plates: 23'400 units, size per unit: 1030 x 790 x 0.4 mm, material Al 99.9% Income 1 CHF / kg waste aluminum

-

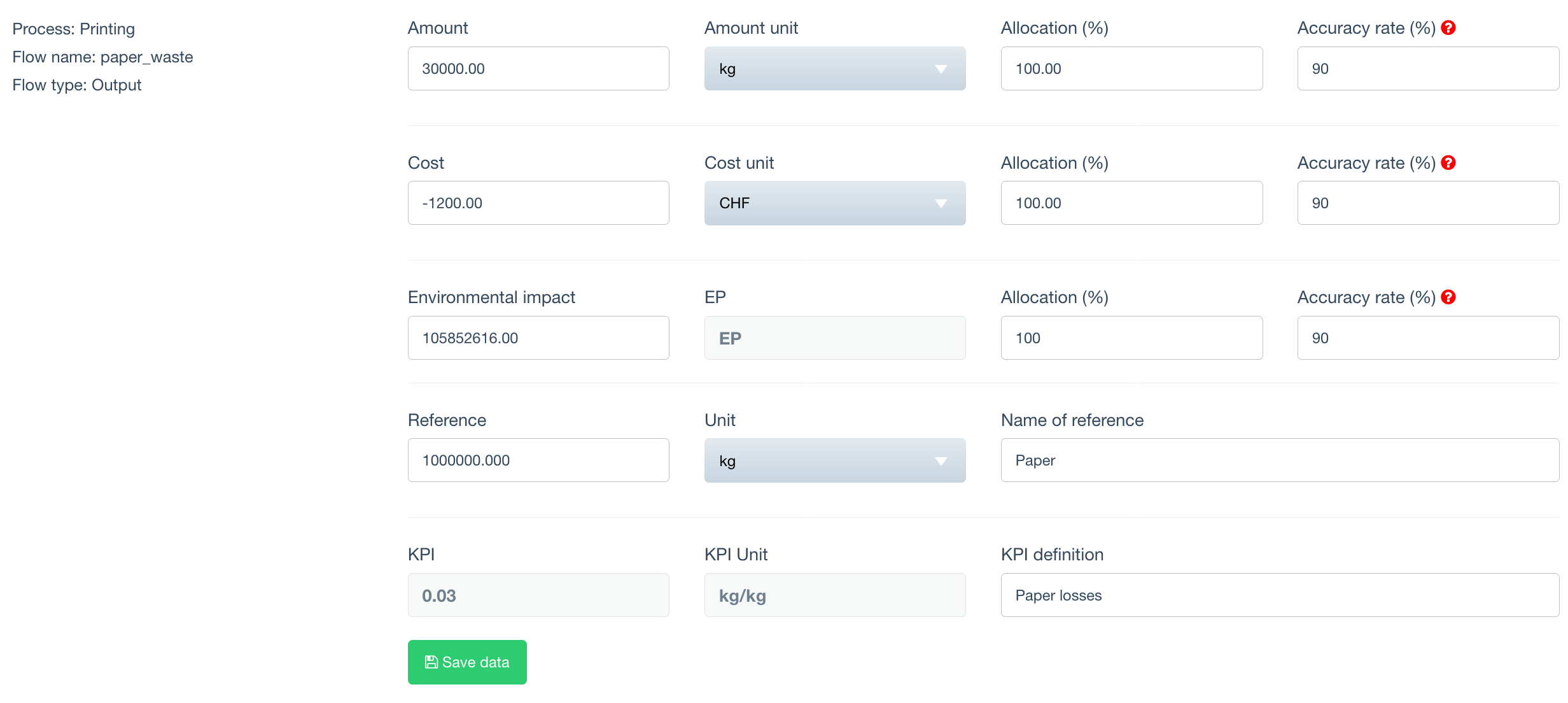

Output: waste graphic paper, 300 tons

Processes

-

Preparation printing (test prints)

-

Offset printing

Products:

-

Magazines, 700 tons

Test_metalsheetcompany:

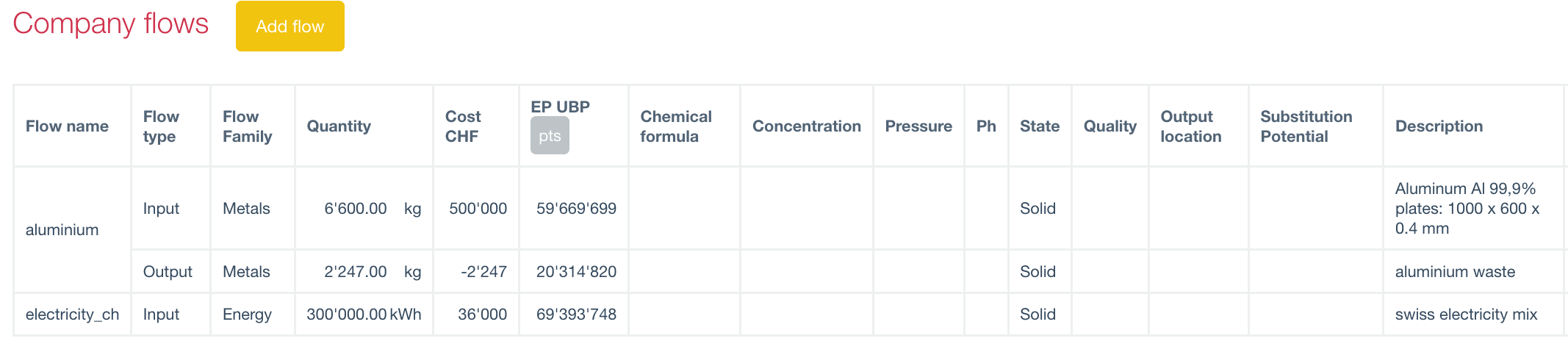

Flows:

-

Input: Aluminum plates: 10’000 units, size per unit: 1000 x 600 x 0.4 mm, weight per unit 0.66 kg (total 6’600 kg), material Al 99.9%, costs: about 50 CHF/unit

-

Input: Electricity: 300'000 kWh, costs 0.12 CHF/kWh

-

Output: Aluminum waste from laser cutting 2247 kg, Income 1 CHF / kg waste aluminum

Processes:

-

Laser cutting of Al-plates to a final size of 0.4 x 600 x 800 mm, 50% of the electricity is used for this process

Products:

-

10’000 Al-plates of a size of 0.4 x 600 x 800 mm (4’353 kg)

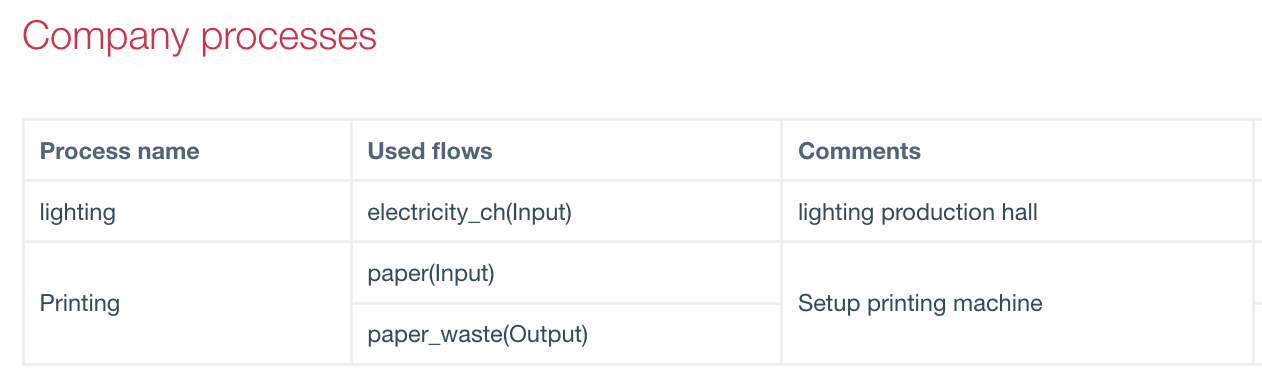

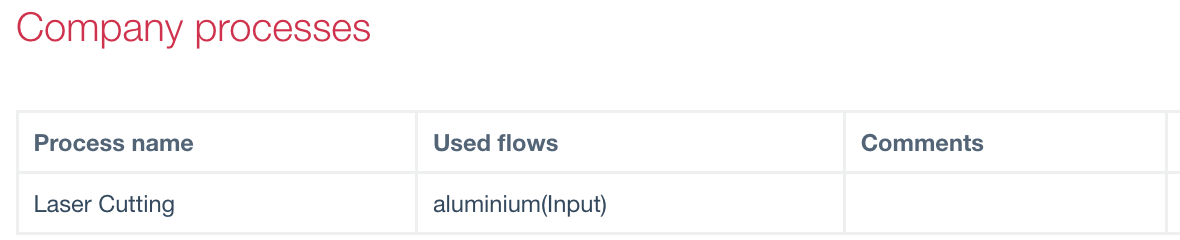

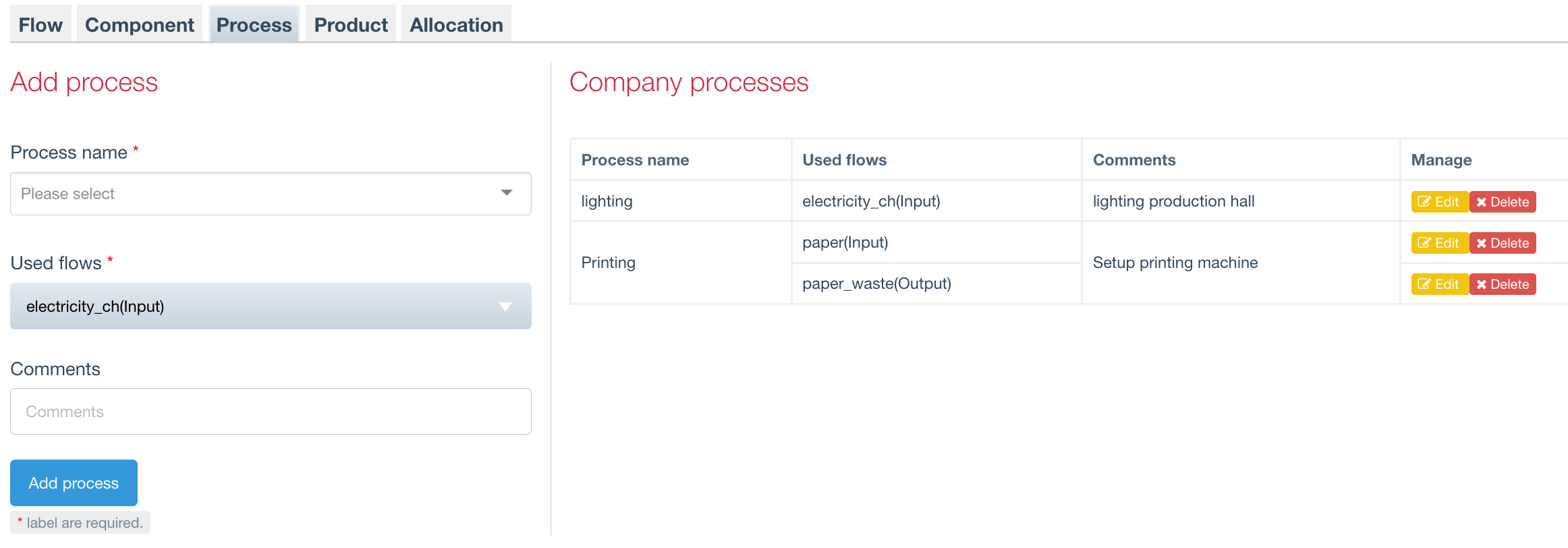

4. Link flows to processes

Data set management

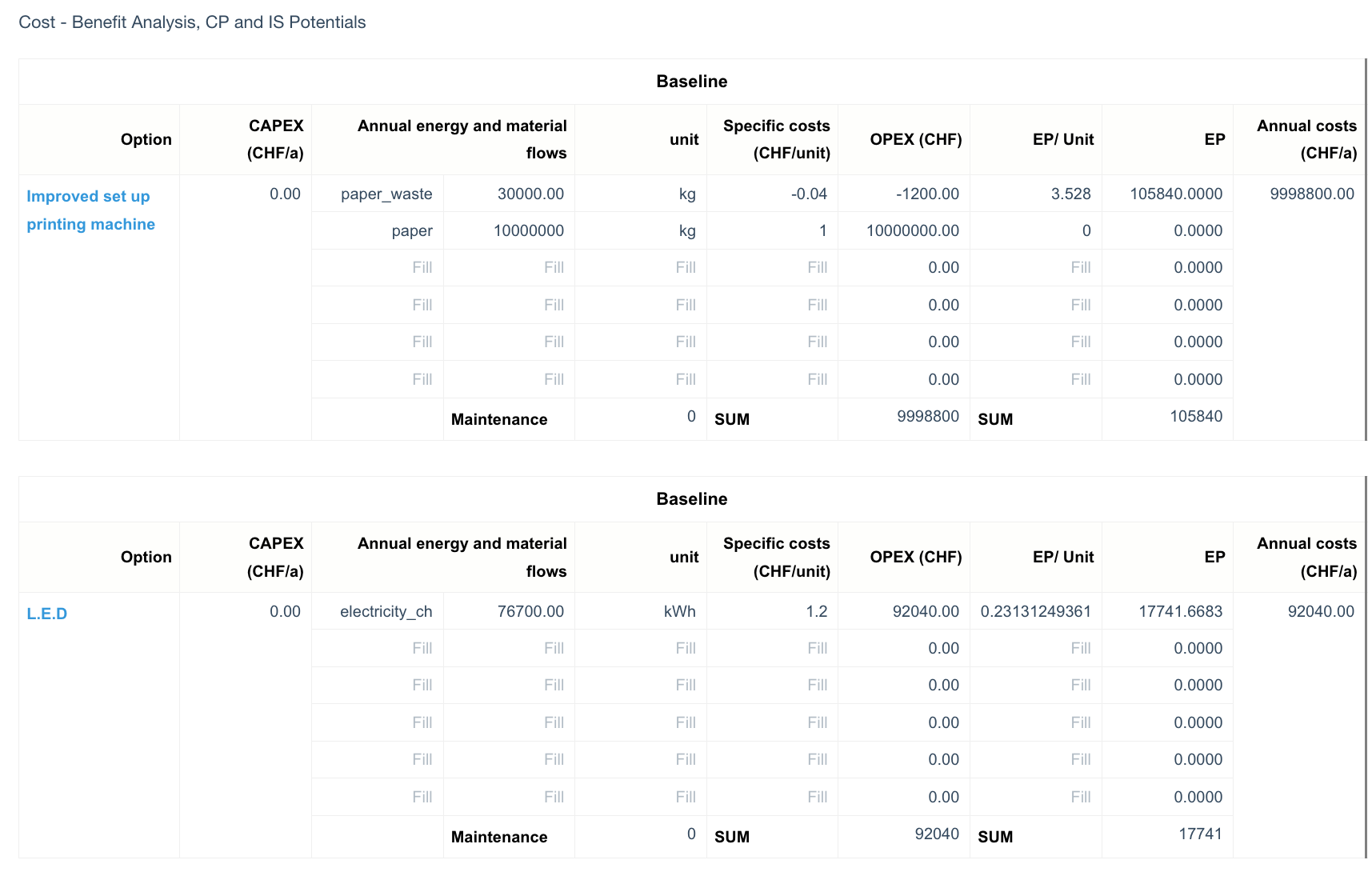

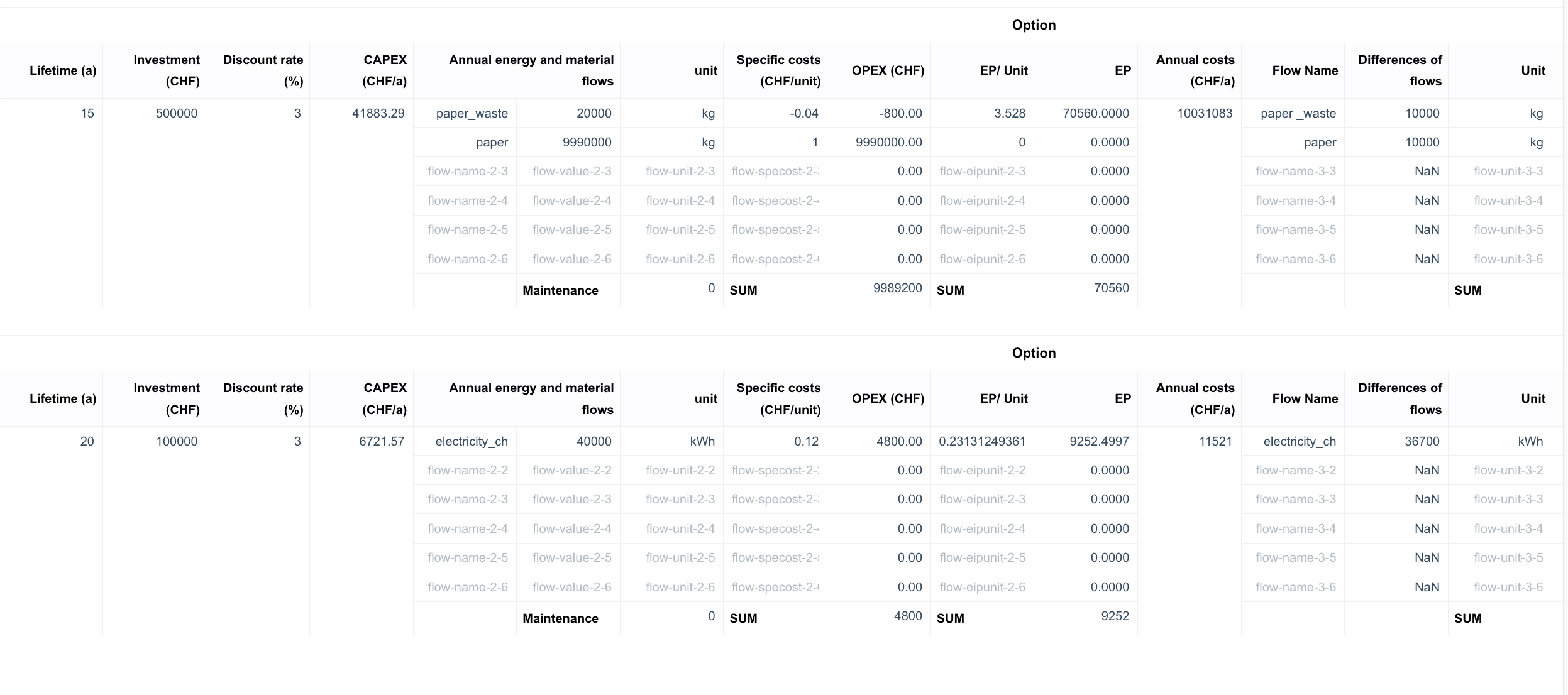

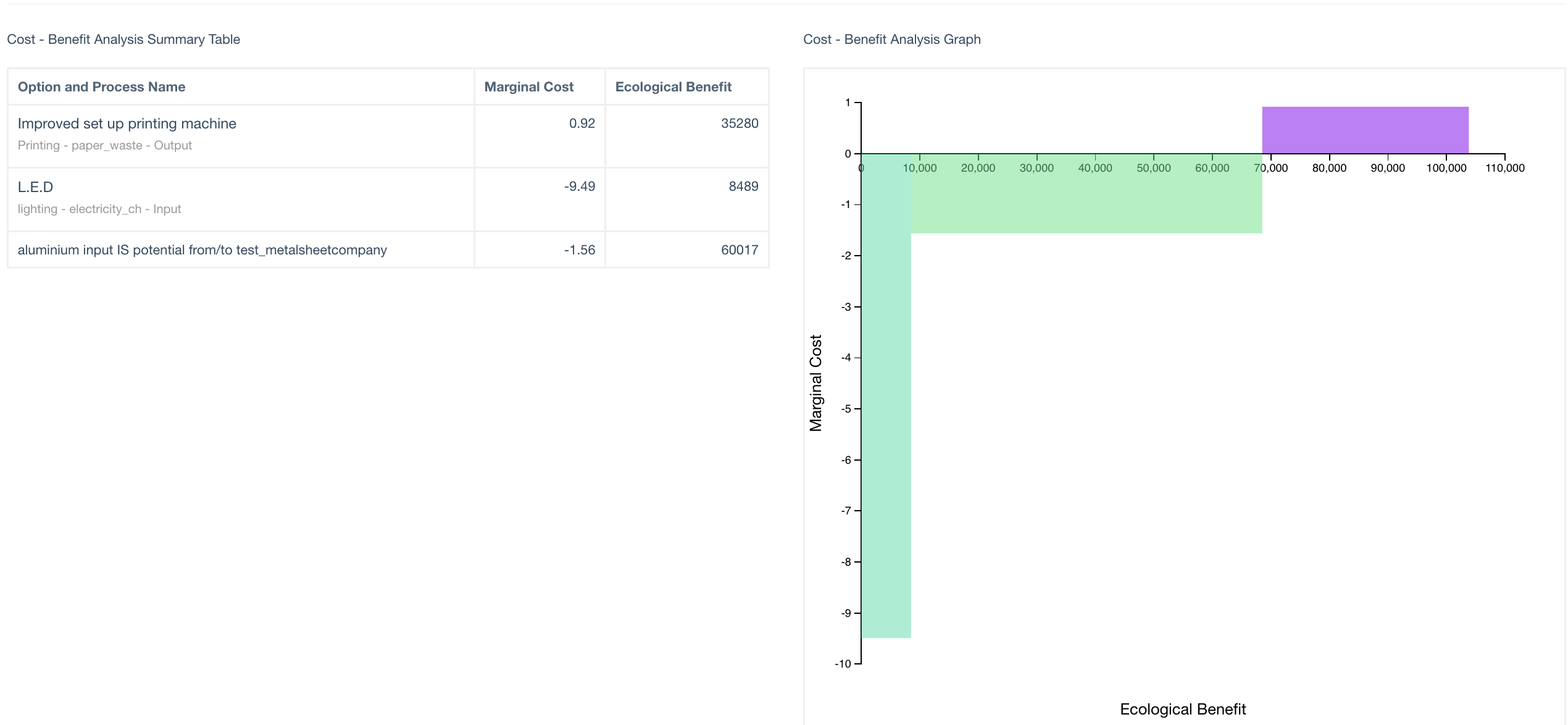

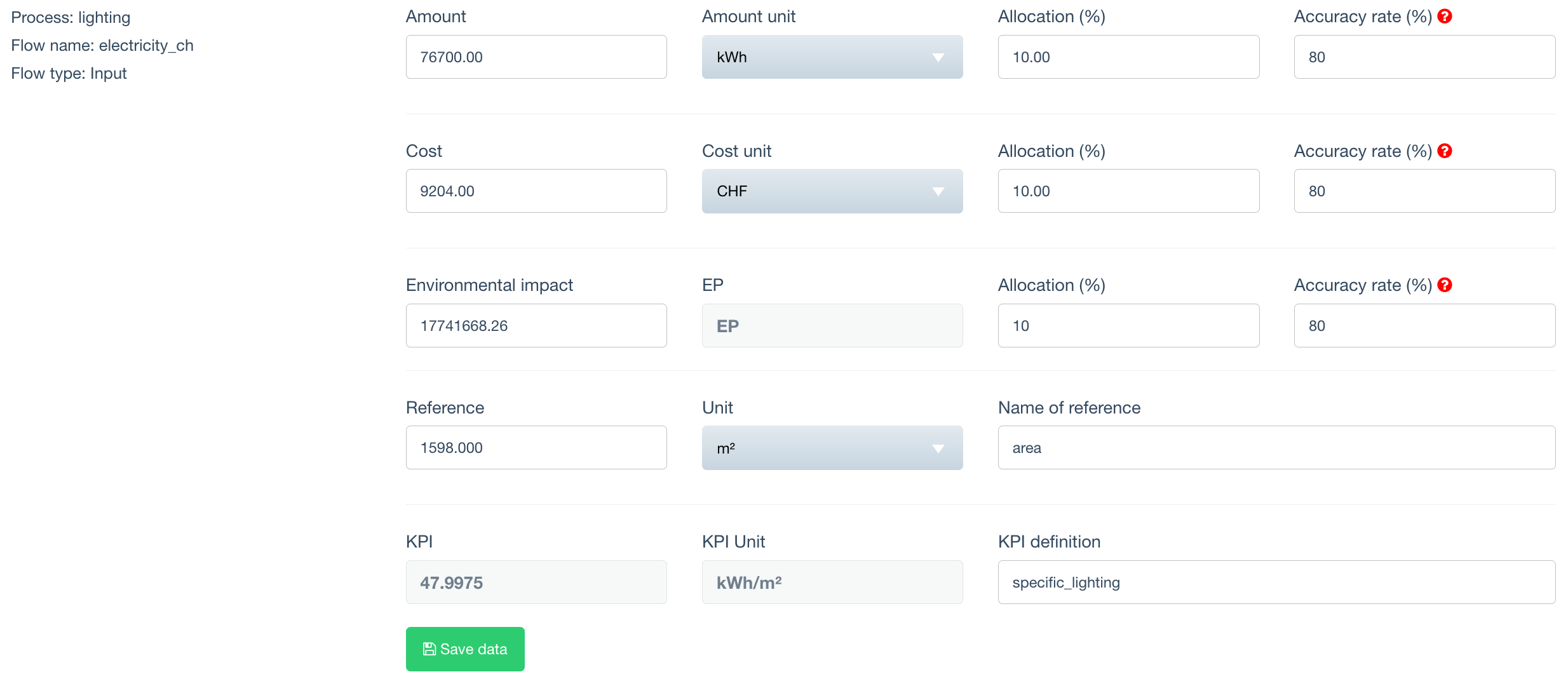

Identification of CP measures – Create allocation

-

Lighting process

-

Printing process

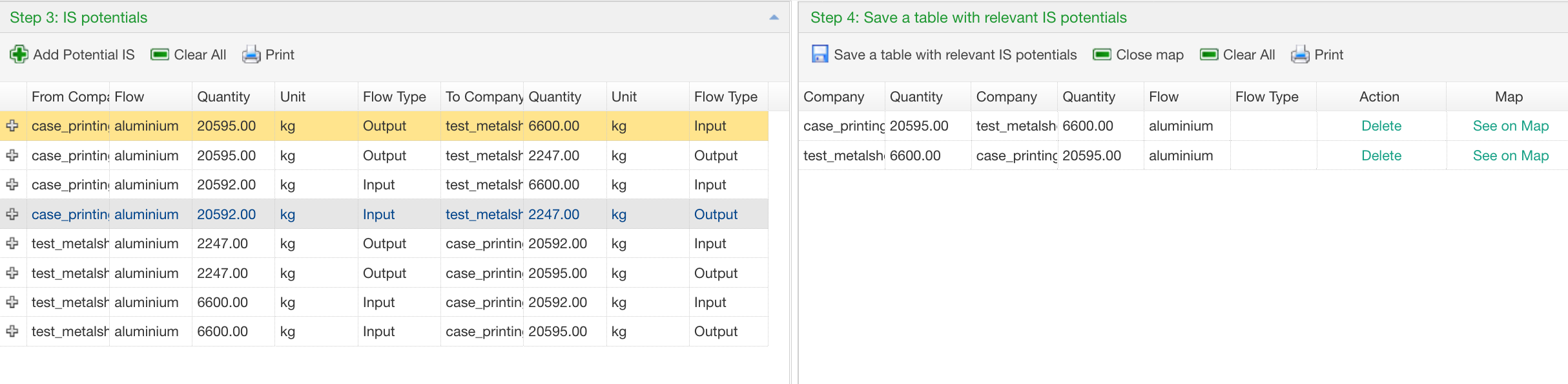

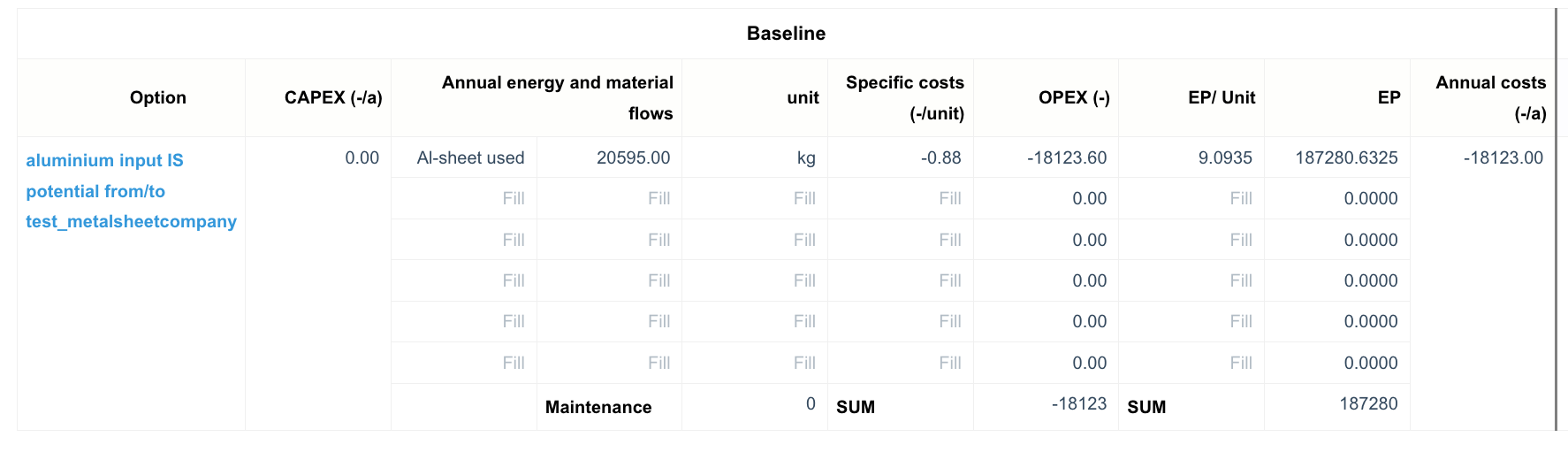

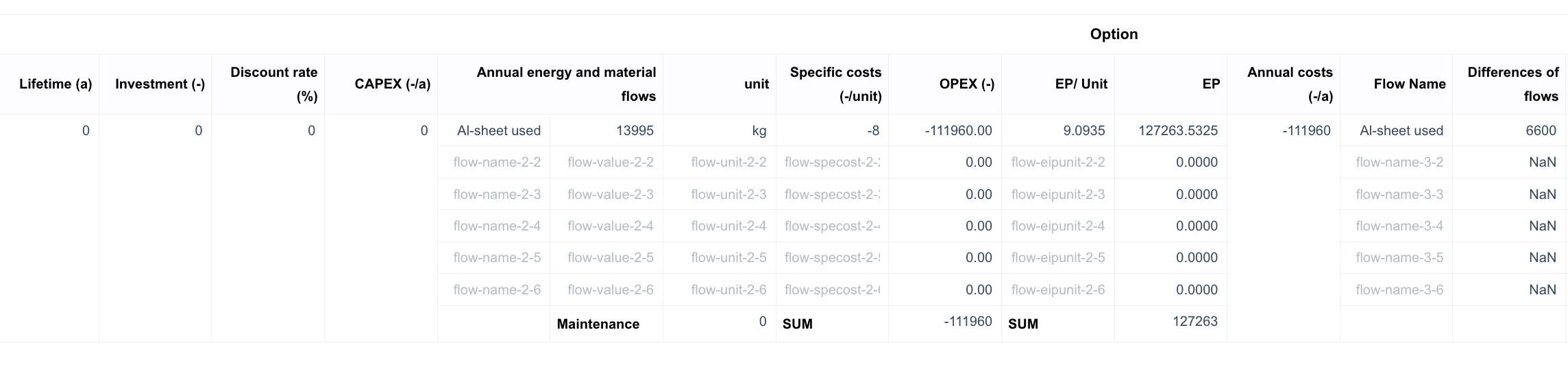

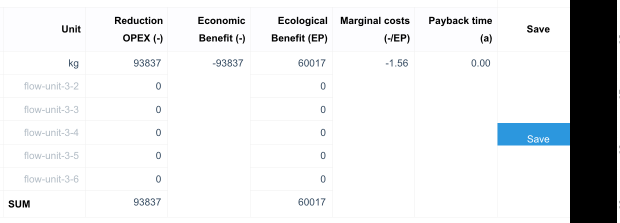

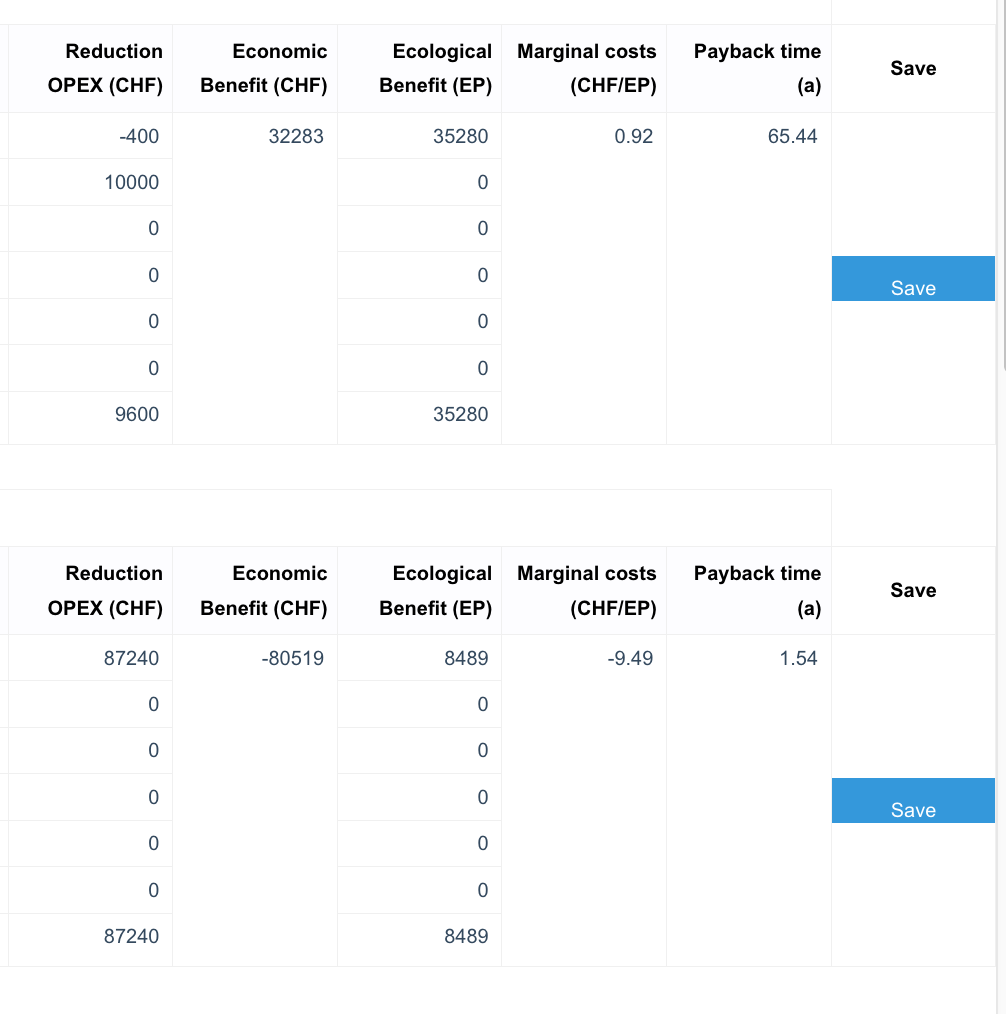

IS -Potential Laser cutting company:

-

Substitution of the Aluminium plates by used offset printing plates from the offset printing company.